REFRACTORY MATERIALS FOR THE CEMENT INDUSTRY

Teide offers a wide range of high and medium-alumina materials and provides services for the setting up of furnaces for the cement industry. These are high performance refractories that can withstand mechanical stress, chemical aggression and thermic start/stop shocks. Our masses, concretes and anchorings are used for the construction of different parts of the kiln: burners, inlets (bends and cooler’s booths), suspension pre-heaters, cyclones and risers, pre-chambers and ramps for unfired material and kiln inlet rings. Clinker combustion and unloading areas, satellite coolers

For these areas of the furnace we offer refractory masses and concretes with following characteristics:

:· High resistance to abrasion and mechanical/thermic shocks. :· Reinforced with steel fibers. :· Fitted out with a fast humidity-elimination system that reduces the start time. These materials are delivered in crates and sacks, in different formats.

Zonas de alimentación de crudo y de unión con el intercambiador

Three ranges of materials from Grupo Pyroterm are aimed at these uses: :· Refractory concretes: High content in silicon carbide, anti-abrasive materials, alkali-repellents. :· Anti-alkali protection plaster. :· Shaped pieces.

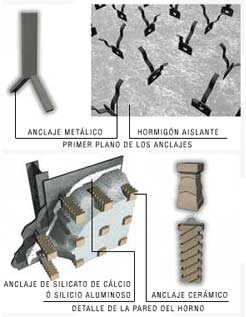

Anclajes cerámicos y metálicos Anchorings that are developed for each type of refractory product and prevent the detachment of the bracket from the metal construction. They have been specially designed to withstand corrosion.