Simulation, Ceramic

EXTRUSION SIMULATION 6 of 6

The technical team, along with the Simulation Department at TEIDE REFRACTORY SOLUTIONS, fully supports the use of finite element software to improve the extrusion process for refractory parts.

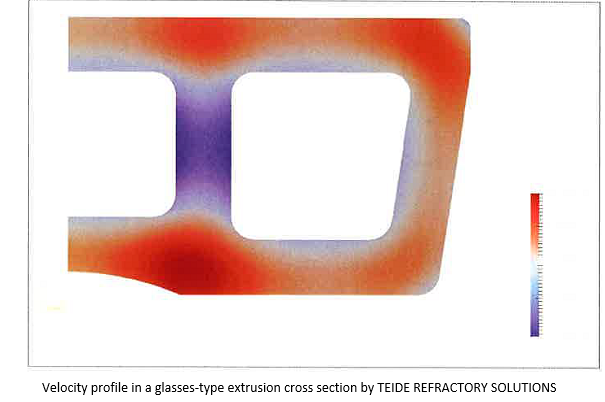

This series of posts on the extrusion of shaped refractory products is closed with an example of a simulation of the extrusion process for a refractory material. Based on the results obtained from the numerical simulation, reengineering can be performed to achieve extruded parts of optimal quality.

Velocity profile in a glasses-type extrusion cross section by TEIDE REFRACTORY SOLUTIONS

As mentioned at the beginning of this series, it is extremely important to:

- Understand the extrusion paste as a fluid.

- Characterise the paste correctly in the pilot plant.

- Anticipate the behaviour of nozzles via simulation with CFDTEIDE®,

- Implementet an extensive system for continuous improvement and control in manufacture.

- Accumulate experience in nozzle design.

Make sure to contact our sales team if you require advice on how to obtain the best refractory solutions.