Ceramic, Simulation

TEIDE REFRACTORY SOLUTIONS HAS CONDUCTED COMPARATIVE STUDIES ON DIFFERENT KILN CAR TECHNOLOGIES

The TEIDE REFRACTORY SOLUTIONS simulation team has conducted a detailed study of two kiln car technologies, comparing the accumulated energy consumption, also known as sensible heat, of each kiln car. The accumulated energy, or sensible heat, has been analysed under different temperature gradients.

To do this, a finite element model has been prepared for a CUSTOMER kiln car and a TEIDE kiln car, assigning the properties corresponding to each material.

Finite element model for a CUSTOMER kiln car. Average density 1,480 kg / m3

-

Finite element model for a TEIDE kiln car. Average density 1,020 kg / m3

-

The following video indicates the thermal development of the various kiln cars on a 20h gradient.

The following graph shows the sensible heat stored by the CUSTOMER kiln car and the TEIDE kiln car for the different temperature gradients of 10 hours, 20 hours, 30 hours and 40 hours.

The above graph shows that the TEIDE kiln car accumulates less sensible heat than the CUSTOMER kiln car in any of the gradients studied.

The accumulated sensible energy of the two kiln car technologies studied upon exiting the furnace is indicated below.

The TEIDE kiln car always has less loss in the form of sensible heat than the CUSTOMER kiln car. Therefore, using TEIDE kiln cars represents direct savings, depending on the gradient analysed.

The model under consideration indicates a consumption minimum of approximately 20h. From this optimum, the longer the cycle the greater accumulation of energy in the form of sensible heat.

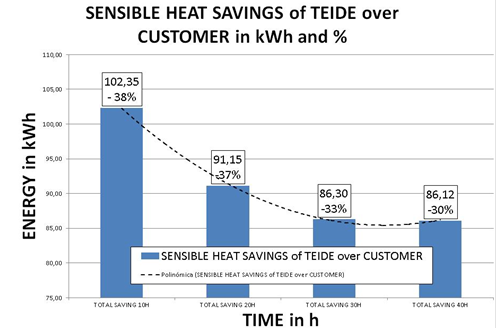

Finally, the following graph indicates energy savings in the form of sensible heat (in kWh and in %) in the use of the TEIDE kiln car with respects to the use of the CUSTOMER kiln car.